Comprehensive Guide to Hydraulics and Pneumatics

Hydraulics and pneumatics represent engineering innovation, embodying the principle of fluid power transmission to induce motion and functionality in machines. These robust systems find their roots in the fundamental laws of physics, seamlessly interweaving with modern-day engineering marvels to foster enhanced performance, reliability, and efficiency. Hydraulic and pneumatic systems are found across a myriad of industries—ranging from manufacturing, construction, and automotive to aerospace.

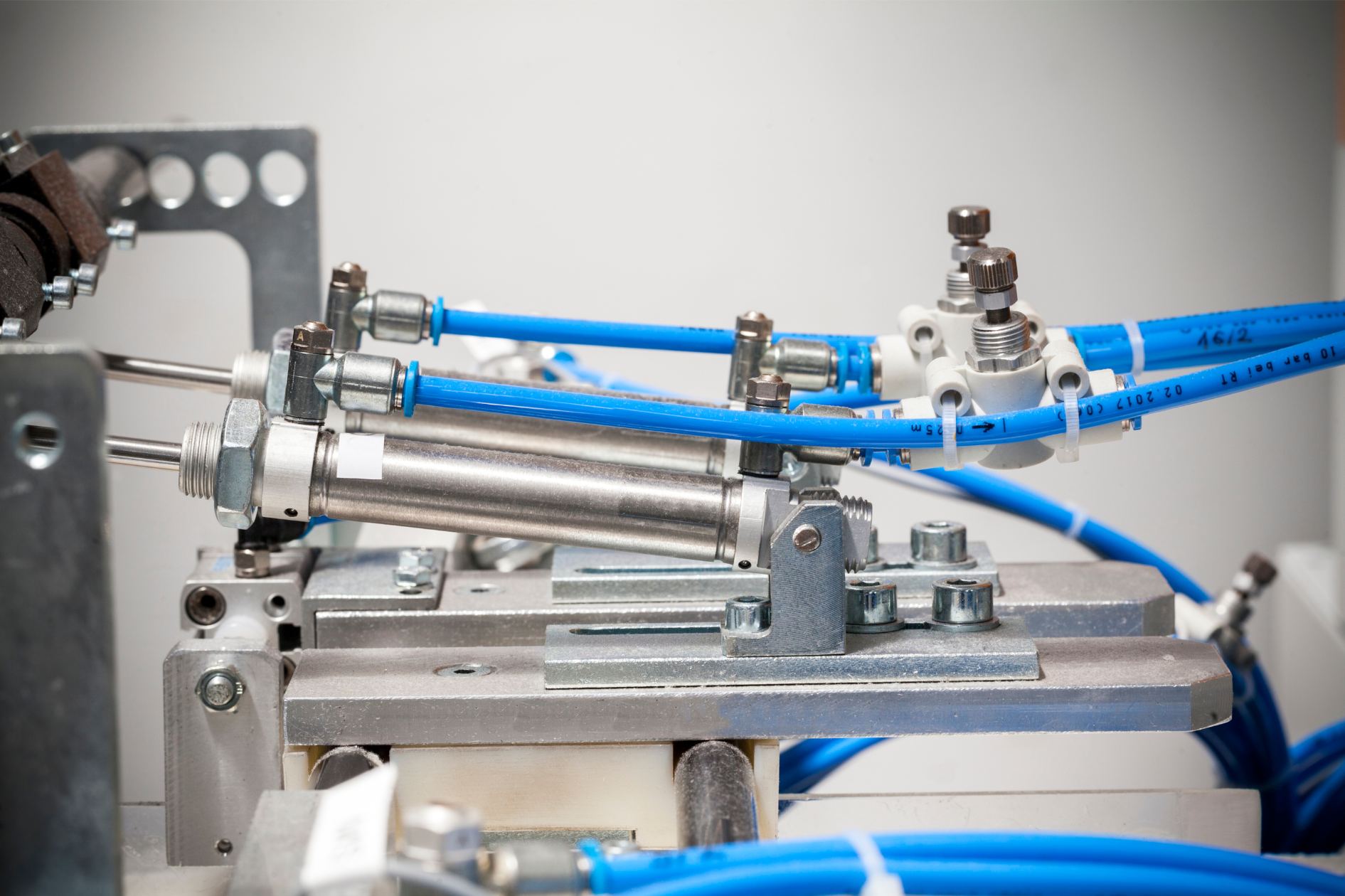

The depth of applications afforded by hydraulics and pneumatics are boundless, transcending conventional boundaries to offer solutions tailored to the requirements of different industrial domains. Be it the the precision-controlled robotic arms in sophisticated manufacturing units, or use in our custom manufactured saws, or the high-performance braking systems ensuring vehicular safety, the essence of hydraulics and pneumatics is ingrained in each of these marvels.

This guide is crafted to guide you through the intricacies of hydraulics and pneumatics, delineating their core principles, functionalities, and distinguishing attributes.

Understanding Hydraulics: The Power of Liquids

Hydraulics is a pivotal branch of engineering that focuses on the mechanical properties and use of liquids. It employs the fundamental principles of fluid dynamics to create, control, and transmit power. In the heart of a hydraulic system lies the incompressible nature of liquids which is harnessed to execute various industrial and mechanical tasks with a degree of efficiency and control that is often unparalleled.

Core Fundamentals of Hydraulics

- Incompressibility and Continuity: Liquids are essentially incompressible, a trait that ensures a consistent flow rate through the system. This characteristic, governed by the principle of continuity, ensures that hydraulic systems operate with a high degree of predictability and precision.

- Pascal’s Law: At the cornerstone of hydraulic systems is Pascal’s Law which states that a change in pressure applied to an enclosed fluid is transmitted undiminished to all portions of the fluid and to the walls of its container. This principle enables the effective multiplication of force, making hydraulic systems a powerhouse for a multitude of heavy-duty applications.

- Flow Rate and Pressure: The efficacy of a hydraulic system is often dictated by the flow rate and pressure of the liquid. Flow rate determines the speed of operation while pressure ascertains the force exerted. Mastery over these variables allows for the fine-tuning of hydraulic systems to meet the rigorous demands of varied applications.

Salient Characteristics of Hydraulic Systems

- High Power Density: Hydraulic systems boast a high power-to-size ratio. This high power density makes them a preferred choice for applications where substantial force is required in confined spaces.

- Precise Control and Accuracy: The meticulous control over liquid flow and pressure grants hydraulic systems a high degree of accuracy and control, making them indispensable in scenarios demanding precision.

- Energy Efficiency: The capacity to store potential energy efficiently, coupled with the ability to handle high loads, renders hydraulic systems energy efficient, thus often proving to be cost-effective in the long run.

Prevalent Applications of Hydraulic Systems

The universality of hydraulic systems is reflected in their wide array of applications across different industrial sectors:

- Industrial Machinery: Hydraulic systems drive the functionality of numerous industrial machines such as presses, hydraulic jacks, and lift tables, ensuring seamless operations in manufacturing facilities.

- Construction and Heavy Equipment: The brute force required in construction equipment like excavators, bulldozers, and backhoes is amply supplied by hydraulic systems.

- Transportation: Essential systems in automotive and aerospace sectors like braking systems and landing gear operations are often empowered by hydraulics.

- Renewable Energy: The burgeoning field of renewable energy also witnesses the application of hydraulics, notably in hydroelectric power stations and wave energy generation.

Delving into Pneumatics: The Power of Gases

Pneumatics is a fascinating facet of engineering that taps into the properties of gases, chiefly air, to create and transmit energy. Unlike hydraulics, which exploits the incompressible nature of liquids, pneumatics capitalizes on the compressibility and elasticity of gases to perform work. Its applicability is wide-reaching, spanning across various industries due to its lightweight, clean, and agile nature.

Underlying Principles of Pneumatics

- Compressibility and Elasticity: The inherent compressibility and elasticity of gases are pivotal to the functionality of pneumatic systems. These properties allow for the storage and release of energy, facilitating dynamic operations across a multitude of applications.

- Boyle’s Law: Boyle’s Law, which states that the pressure and volume of a gas are inversely proportional at a constant temperature, forms a fundamental base for understanding and working with pneumatic systems. By adjusting the pressure, one can manipulate the volume of the gas, and thus, control the energy transmission within the system.

- Flow and Pressure Control: The control of flow rate and pressure are crucial for fine-tuning the performance of pneumatic systems. These variables are adjusted to meet the specific demands of different applications, ensuring both efficiency and effectiveness.

Notable Attributes of Pneumatic Systems

- High-Speed Operation: Pneumatic systems are revered for their ability to operate at high speeds, making them a suitable choice for applications requiring rapid, cyclic operations.

- Simplicity and Economy: The simplicity in design and the use of air as the primary medium makes pneumatics an economical and easy-to-maintain option. Moreover, the abundance and ease of compressing air contribute to the cost-efficiency of pneumatic systems.

- Safety and Cleanliness: The use of air, a clean and safe medium, makes pneumatics an attractive option in environments where hygiene and safety are paramount, such as the food and pharmaceutical industries.

Broad-Spectrum Applications of Pneumatic Systems

The adaptability and versatility of pneumatic systems are mirrored in their broad range of applications:

- Industrial Automation: Pneumatic systems play a critical role in automation, powering a plethora of automated machinery and robotic systems to enhance productivity and precision.

- Pneumatic Tools: The range of pneumatic tools like air hammers, drills, and wrenches is extensive, assisting in various construction and manufacturing tasks.

- Medical Devices: In the medical domain, pneumatics propels devices like ventilators and pressure cuffs, underscoring its importance in critical life-saving applications.

- Transport Systems: Pneumatic technology also finds its way into modern transportation systems, aiding in brake systems and automatic doors, among others.

Hydraulics vs Pneumatics: Uncovering the Distinctions

The dichotomy of hydraulics and pneumatics is rooted in the contrast between the mediums they employ—liquids and gases respectively. While both mechanisms fall under the broad umbrella of fluid power technology, their differences carve distinct applications and efficiencies in the industrial realm. This section meticulously delineates the contrasting characteristics and application domains of hydraulic and pneumatic systems.

Fundamental Discrepancies

- Medium of Operation:

- Hydraulic systems operate using liquids, primarily oil, which are incompressible.

- Pneumatic systems utilize gases, chiefly air, which are compressible and exhibit elasticity.

- Operational Pressure Range:

- Hydraulics often operates at higher pressures, typically ranging from 1,000 to 5,000 psi.

- Pneumatics operates at lower pressures, usually between 80 to 100 psi.

- Compressibility:

- The incompressibility of liquids confers precision and power to hydraulic systems.

- The compressibility of gases lends pneumatics a level of springiness, making it adept for applications requiring cushioning effects.

Performance Characteristics

- Power Density:

- Hydraulics boasts a higher power density due to the incompressible nature of liquids, making it suitable for heavy-duty and high precision applications.

- Pneumatics, with its lower power density, caters to lighter, high-speed operations.

- Control and Accuracy:

- Hydraulic systems offer superior control and accuracy, crucial for applications demanding meticulous force or position control.

- Pneumatic systems, while capable of control, may not match the precision levels achievable with hydraulics.

- Speed of Operation:

- Pneumatics excels in high-speed, cyclic operations due to the compressibility of gases and simpler system designs.

- Hydraulics, while capable of varying speeds, might not match the rapid actuation of pneumatic systems.

Maintenance and Environment

- Maintenance Needs:

- Hydraulic systems may necessitate more rigorous maintenance to prevent and address leaks, and ensure clean, moisture-free oil.

- Pneumatic systems generally require lesser maintenance due to the self-cleaning and self-cooling attributes of compressed air.

- Environmental Impact:

- Hydraulic leaks can pose environmental hazards and may require careful disposal of used oil.

- Pneumatics is environmentally benign with air being exhausted into the atmosphere post-operation.

Tailoring to Applications

The contrast between hydraulics and pneumatics directs their appropriateness for different application domains:

- Heavy Machinery and Construction: The formidable power of hydraulic systems makes them the go-to choice for heavy machinery and construction equipment.

- High-Speed Manufacturing and Assembly: The high-speed actuation of pneumatic systems makes them ideal for manufacturing lines and assembly operations.

- Medical and Food Industries: The clean, safe operation of pneumatic systems fits well within the stringent hygiene requirements of the medical and food industries.

Concluding Remarks

The profound understanding of hydraulics and pneumatics is essential for engineers and technicians to aptly utilize these systems. Each holds its own set of advantages and suitability for different applications, dictating their selection based on the specific needs of a project. Through this detailed exposition, the intrinsic value and the distinguishing facets of hydraulics and pneumatics are thoroughly illuminated, fostering informed decision-making in engineering endeavors.