Portable Yard Saw – Your Guide To Efficiency And Precision

When it comes to timber processing and handling, the quality and efficiency of your equipment can significantly influence your output. The portable yard saw is an instrumental device in this regard. Let’s delve into the ins and outs of the portable yard saw, understanding its advantages, essential features, and why it stands out as a critical tool for timber management.

Key Features of the Portable Yard Saw

Efficient Blade System

The blade system in a portable yard saw is designed for maximum efficiency. Its sharpness, durability, and speed ensure that every cut is precise, minimizing wastage.

Robust Engine Performance

A powerful engine drives these yard saws, ensuring consistent performance. This means reduced downtime and increased productivity.

Ease of Portability

As the name suggests, one of the standout features of the portable yard saw is its portability. It is designed for ease of transport, making it suitable for different terrains and onsite projects.

Safety Mechanisms

Safety can never be compromised. These saws come equipped with top-notch safety features, ensuring that the user and the equipment remain protected at all times.

Advantages of Using a Portable Yard Saw

1. Cost-Effective Operation

Using a portable yard saw reduces operational costs. Its efficient blade system ensures minimal wastage, translating to more output from every timber piece.

2. Flexibility and Versatility

With its portability feature, this yard saw can be used in multiple locations, making it ideal for businesses with multiple operational sites or those that handle onsite projects.

3. Reduced Downtime

Thanks to its robust engine and durable construction, the portable yard saw promises reduced downtime. This means more hours of operation, leading to increased productivity.

4. Enhanced Safety

With built-in safety mechanisms, operators can feel secure, knowing that the equipment has been designed keeping their safety in mind.

Selecting the Right Portable Yard Saw for Your Needs

When choosing a portable yard saw, consider:

- Blade Quality: Ensure the blade is of high-quality steel and offers durability.

- Engine Power: A powerful engine ensures consistent performance.

- Safety Features: Check for features like auto shut-off, blade guards, and emergency stops.

- Portability Features: Look for designs that facilitate easy movement and transport.

Pacific Trail Manufacturing offers our Mobil-Cut Gas Saw as a solution.

How a Portable Yard Saw Works

The portable yard saw, often regarded as an indispensable tool in timber processing, combines functionality, precision, and efficiency in a compact design. To appreciate its brilliance, it’s essential to understand its operational mechanism. Below is a detailed breakdown of how a portable yard saw functions:

1. Timber Feeding

The process starts with feeding the timber or log into the machine. Most portable yard saws have adjustable guide systems to handle timber of different sizes, ensuring that the timber stays in place and moves steadily.

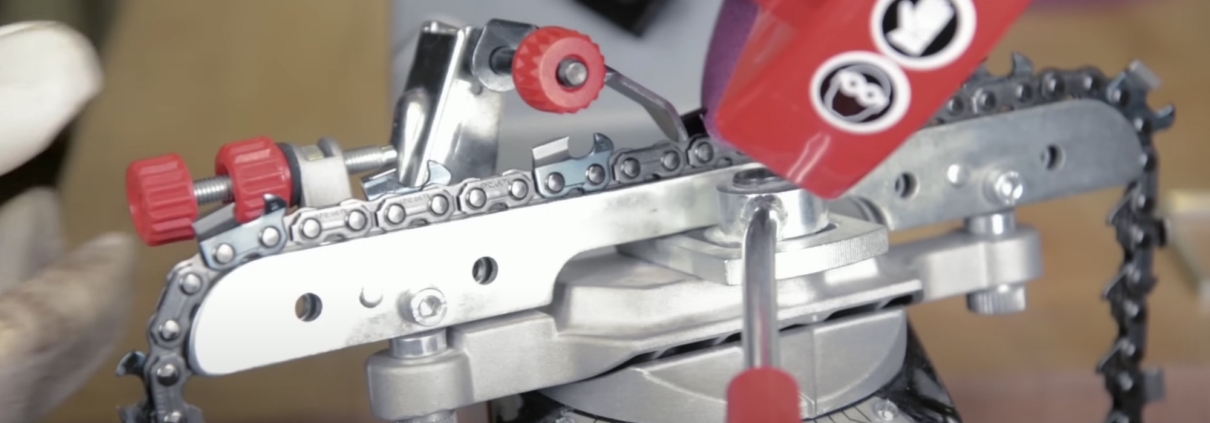

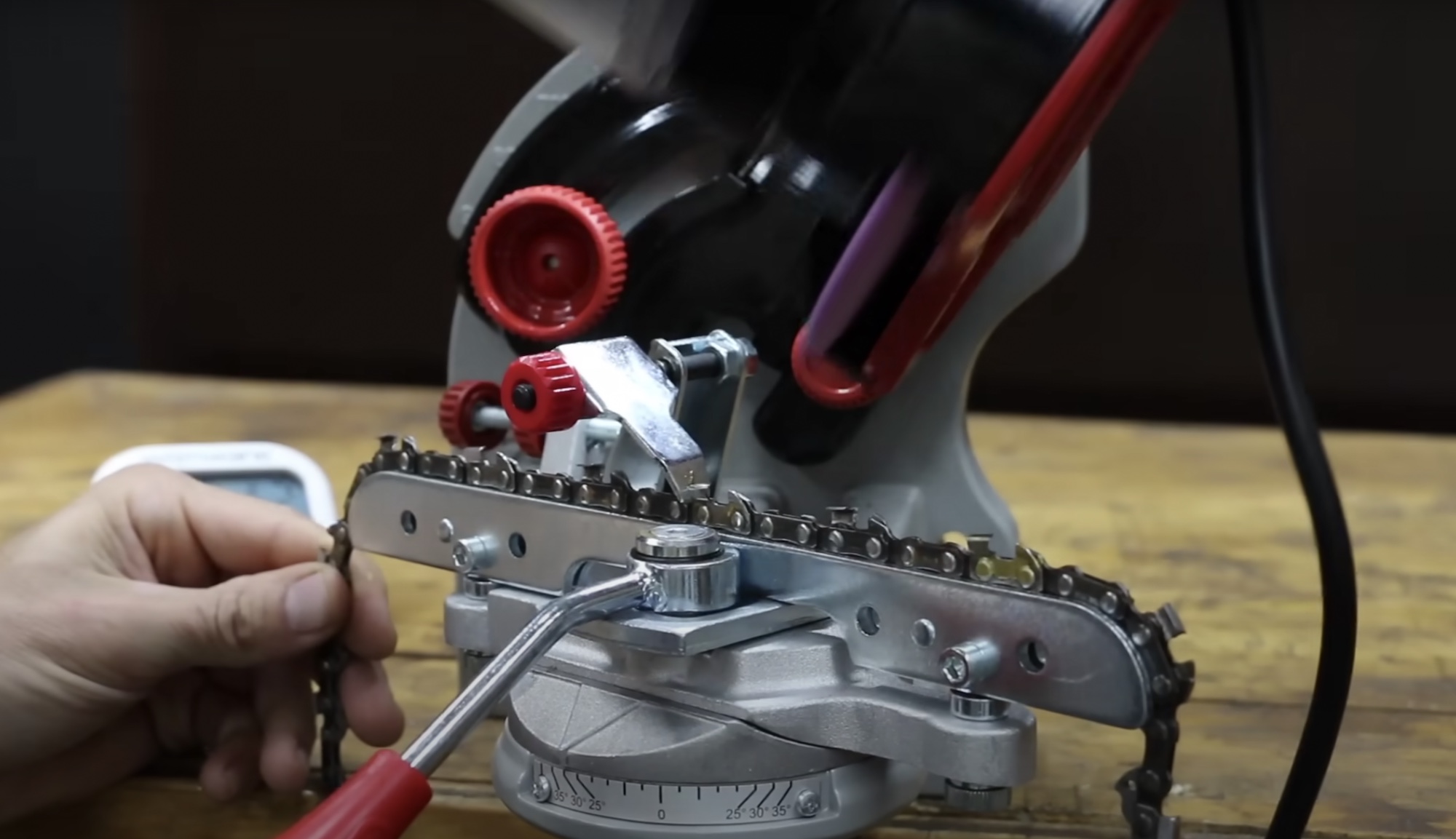

2. Blade Engagement

Once the timber is in position, the next step involves the blade. Driven by a powerful engine, the blade rotates at high speeds. This blade, made of durable materials and often fortified with carbide or other hard metals, is designed to cut through timber with precision and efficiency.

3. Cutting Process

As the timber moves (either manually pushed or automatically fed), the rotating blade slices through it. Depending on the design and setting, the saw can make either crosscuts, which are cuts across the grain, or rip cuts, which are cuts with the grain. Some advanced models may also allow for angled cuts or bevels.

4. Waste Management

The cutting process produces sawdust and small wood chips. Portable yard saws often come equipped with waste management systems. This can be as simple as a chute directing the waste into a collection bag or more advanced systems like integrated dust collectors.

5. Safety Mechanisms in Action

Throughout the cutting process, various safety mechanisms are at play. Blade guards shield the operator from direct contact with the blade. Some models may also feature auto shut-off sensors that detect irregularities or obstructions and shut down the machine to prevent accidents.

6. Completion and Timber Ejection

Once the timber has been entirely cut, it’s either manually removed or ejected through a conveyor system, depending on the model’s design. With the cut timber safely out, the saw is ready for the next piece.

7. Mobility and Transportation

What sets the portable yard saw apart from stationary models is its portability. After the cutting process, the machine can be easily relocated. Features like foldable stands, wheels, or lightweight construction ensure the saw can be moved to different locations or stored conveniently.

In essence, the portable yard saw is a symphony of engineering brilliance. It merges powerful cutting capabilities with safety and portability, providing an efficient solution for timber processing needs. Whether it’s for onsite projects or varied operational sites, understanding its operational dynamics ensures users can harness its full potential.

Conclusion

In the realm of timber management, Pacific Trail Manufacturing’s portable yard saw stands out as an indispensable tool. It offers a perfect blend of efficiency, safety, and portability, making it a must-have for businesses looking to optimize their timber processing operations. Whether you’re looking to enhance productivity, reduce operational costs, or ensure the safety of your personnel, the portable yard saw ticks all the boxes. By understanding its features and benefits, you can make an informed decision that can elevate your timber management processes.